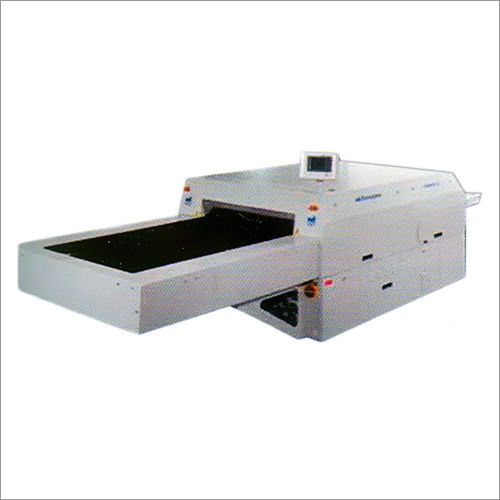

Veit Fusing Machine

Product Details:

X

Product Description

Veit Fusing Machine (Fx Diamond)

Features:- Optimal fusing results thanks to exact temperature control directly at the belt

- Consistent fusing results due to consistent pressure over the entire operating width

- Optimal adjustment of pressure system (soft, medium) and heating sequence (top, bottom) to the materials to be processed

- Perfectly designed service concept allows easy and regular cleaning of machine

- Lowest possible energy consumption due to: separate feeding belt, no cooling of transport belt outside of machine complete encapsulation of heating units for extremely low heat loss decoupling of heating zones from machine frame

- Separate feeding belt, no cooling of transport belt outside of machine

- Easy operating with new 7'' colour touch display

- Reduced wear and tear of belt edge through contact-free belt detection

- Prevention of faulty fusing through start/stop function in the event of a diversion from pre-set fusing parameters. This allows the operator to step in

- Consistent fusing quality due to optimized cleaning of the belts both on the inner and the outer side. Consequently, major reduction in soiling of roller and fusing material

Enter Buying Requirement Details

Other Products in 'Veit Fusing Machine' category

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

GST : 29AAACR8787Q1Z6

GST : 29AAACR8787Q1Z6

No.1/4, 1st Floor, Off Ulsoor Road, Hanumanthappa Layout, Sivanchetti Gardens,

Bengaluru - 560042, Karnataka, India

Phone :08045802917

|

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |